Standard

welding cells

MPARC COMPACT

ROBOTIC

WELDING CELL

KP1M

single KR

ROBOTIC

WELDING CELL

KP1A

single KR

ROBOTIC

WELDING CELL

KP3-V2H

single KR

ROBOTIC

WELDING CELL

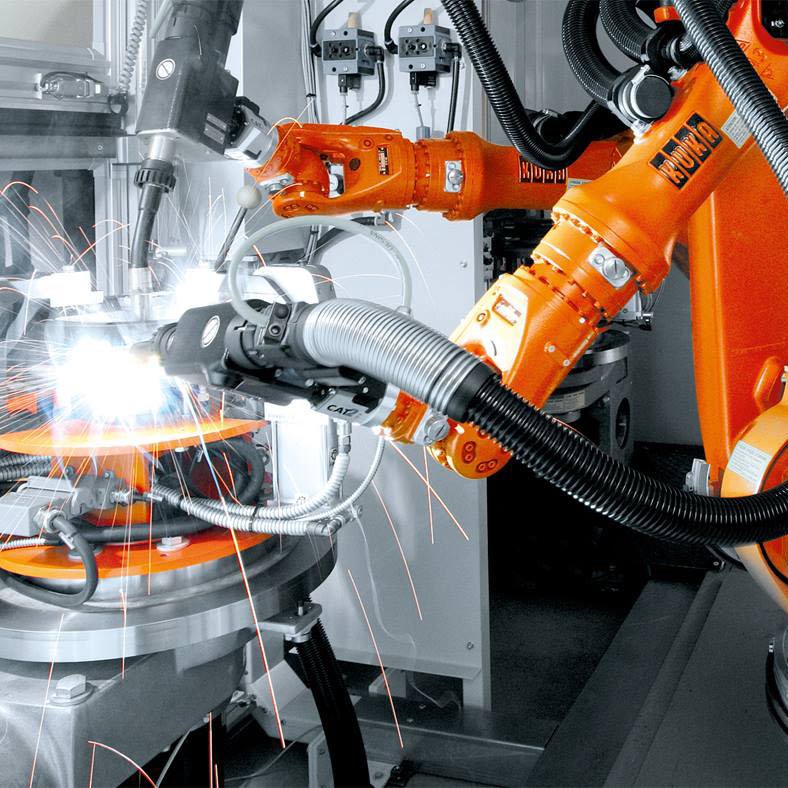

ROBOTISATION

OF WELDING

Robotised welding is the most commonly automated production process. The use of welding robots is a natural development for any company specialising in serial and repetitive repeatable workpiece welding.

For our customers, robotisation of welding has a direct impact on the benefits achieved – an increase in productivity, better quality of the products manufactured and a reduction in production costs.

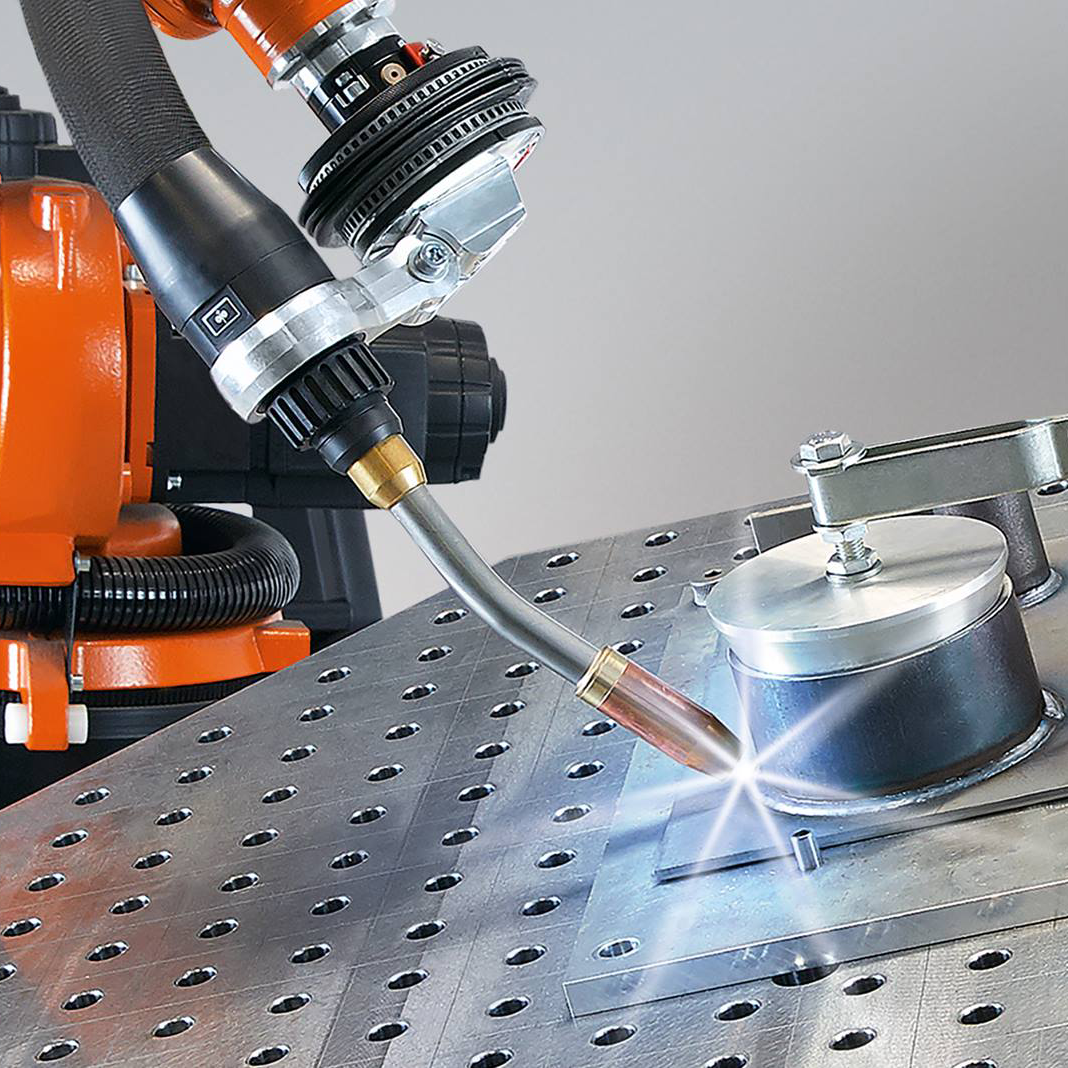

Welding with a robot arm increases quality and repeatability of the welds made. The welding robot allows much better control over welding while ensuring constant fusion parameters.

Our cells are equipped with a welding robot and a KUKA positioner as well as Fronius welding equipment. We propose the simplest, most effective way to robotise welding in your company.

As one of the very few vendors in the market we offer a “turnkey” service for clients who, for various reasons, do not want or cannot participate in the implementation process themselves. In such cases, we assume full responsibility for production coordination and implementation.

File type: pdf

WELDING CELLS

THANKS TO MPLAB SOLUTIONS THEY ARE

Ready

for use

The cell is supplied complete,

ready for connection and commissioning,

ensuring that production

can begin immediately.

Compact

design

The welding cell takes up

little space on the shop floor,

thus gaining space for

further machines.

Easy

to use

Can be operated

by a less skilled operator,

thus reducing

production costs.

Easy to

programme

Guiding the robot by hand

allows new workpieces to be

introduced into production quickly

and efficiently, thus reducing implementation time and

enabling robotisation of even

small production runs.

Mobile and

easy to connect

The welding chamber

can be relocated anywhere

with a forklift at any time.

In this way, we manage

production flexibly.

ALL WELDING CELLS

ARE EQUIPPED WITH:

- Automatic tool TCP measurement

- TouchSense – automatic detection of workpiece position by touching with a wire

- Automatic cleaning and trimming station

- ArcSence – automatic weld tracking

GET IN TOUCH WITH US

DIRECTLY WITH OUR SALESMAN

OR VIA THE CONTACT FORM

CONTACT FORM

STANDARD

WELDING

CELLS

INDUSTRIAL

ROBOT

INTEGRATION

PRODUCTION

AUTOMATION

MACHINERY

DESIGN AND

CONSTRUCTION